Unique STIHL Injection engine technology for 350 mm cutting wheels. Easy to start; powerful torque. Fully-equipped with long-life air filter system and electronic water control. Can be operated by hand or with the FW 20 cart. Supplied with abrasive cutting wheel.

Technical specifications | Value |

|---|---|

Displacement | 72,2 cm³ |

Power output | 3,9/5,3 kW/bhp |

Weight ¹) | 10,2 kg |

Sound pressure level ²) | 98 dB(A) |

Cutting wheel | 350 / 14 mm/in |

Sound power level ²) | 112 dB(A) |

Max. cutting depth | 125 mm |

Vibration level left/right ³) | 2,4/2 m/s² |

The electronically controlled fuel injection ensures perfect running properties every time and reduces fuel consumption in comparison with tools without injection technology.

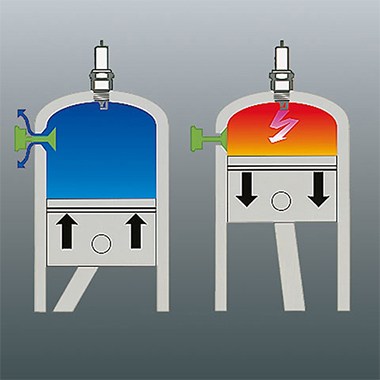

2-stroke engine with stratified charge. A fuel-free layer of air is created between the burned charge in the combustion chamber and the fresh charge in the crankcase, reducing the amount of fuel lost during the charge cycle. This results in more power with a lower weight, up to 20% lower fuel consumption than regular 2-stroke engines and significantly reduced exhaust emissions.

The electronic water control system can be operated via simple buttons while the engine is running. The water then switches on and off during cutting automatially, depending on engine speed. The water volume can be regulated by simply pressing the plus / minus buttons, ensuring optimum dust suppression at the touch of a button.

STIHL ElastoStart reduces the shock caused by the compression of the engine during starting. The compression shock is taken away from the user’s joints and muscles through a spring or rubber element in the starter handle.

The cutting wheel guard made from die-cast magnesium is particularly light. The guard and water attachment feature a particularly ergonomic design.

The modern, ergonomic design allows each user to work with an optimal grip position. The loop handle facilitates excellent cutting comfort in any working position.

STIHL long-life air filtration systems with pre-separation achieve perceptibly longer filter life compared with conventional filter systems. Air drawn in is swirled. The larger, heavier particles are ejected. The pre-cleaned air is routed to the air filter via the pre-separator duct.

A small fuel pump delivers fuel to the carburettor at the touch of a button. This reduces the number of starting strokes required following extended breaks in operations.

The decompression valve allows some of the compression pressure in the cylinder to escape, so less force on the starter rope is needed.

Intense vibration at the handles of power tools can lead to long-term effects on blood vessels in the hands and arms. STIHL has therefore developed an effective anti-vibration system whereby the oscillations from the machine’s engine are dampened which significantly reduces vibrations at the handles.

Light, consistent re-tensioning increases the service life of the belts and shaft bearings.